Function application of special-shaped tension spring

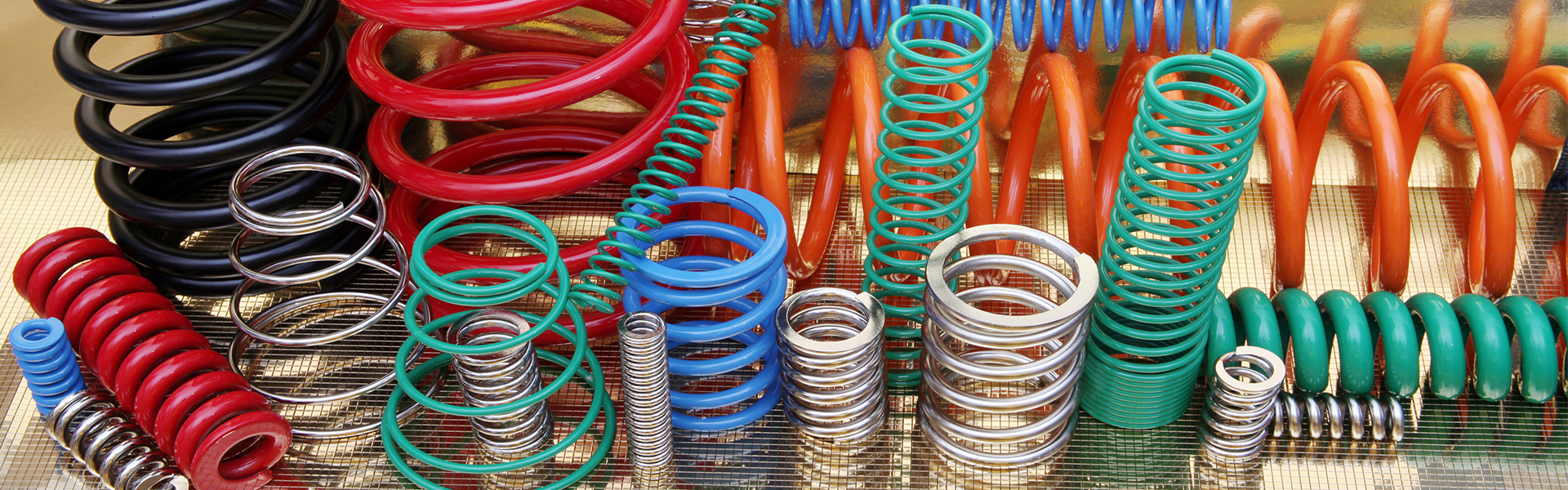

In mechanical products, special-shaped tension springs are widely used. There are many kinds of special-shaped springs with different shapes, sizes and sizes. The special-shaped tension spring is made of steel wire. Its shape is suitable for various types and can also be customized according to the market demand. It is used to monitor the movement of the machine parts, alleviate the impact or vibration, store energy, measure the number of force oil seal springs, etc. It is widely used near the surface of the machine. The varieties of special-shaped tension springs are miscellaneous and diverse.

The basic function of the special-shaped tension spring is that the stainless steel spring can transform the mechanical work or kinetic energy into deformation energy, or transform the deformation energy into kinetic energy or mechanical work, when the deformation occurs and recovers, using the elasticity of the data and the structural characteristics of the spring itself. That is, the size of the stored energy in the spring is a function of the deformation (displacement). The special-shaped tension spring can control the movement of the machine, for example, the clutch is equipped with a monitoring special-shaped tension spring inside. It can absorb the energy of shock and impact, such as the special-shaped tension spring under the car and train carriage to relieve the impact, and so on. In addition, it can also store and release energy and provide kinetic energy for some tissues. This is the first way to use the tension spring and is still widely used now. For example, the tension springs used in various watches, movie cameras and toys. It is used near the force-measuring element, such as the force-measuring device. The ratio of force application and deformation of the tension spring is called the rigidity of the special-shaped tension spring. The greater the rigidity, the harder the special-shaped tension spring is.

In practical production, metal materials with high elastic limit are generally used to make special-shaped elastic yellow. Because of the good formability of metal materials, simple production, and the ability to fully use its elastic deformation energy, it is more economical and reliable.